Industry Review

Introduction to Supply Chain Management: Key Components and Processes

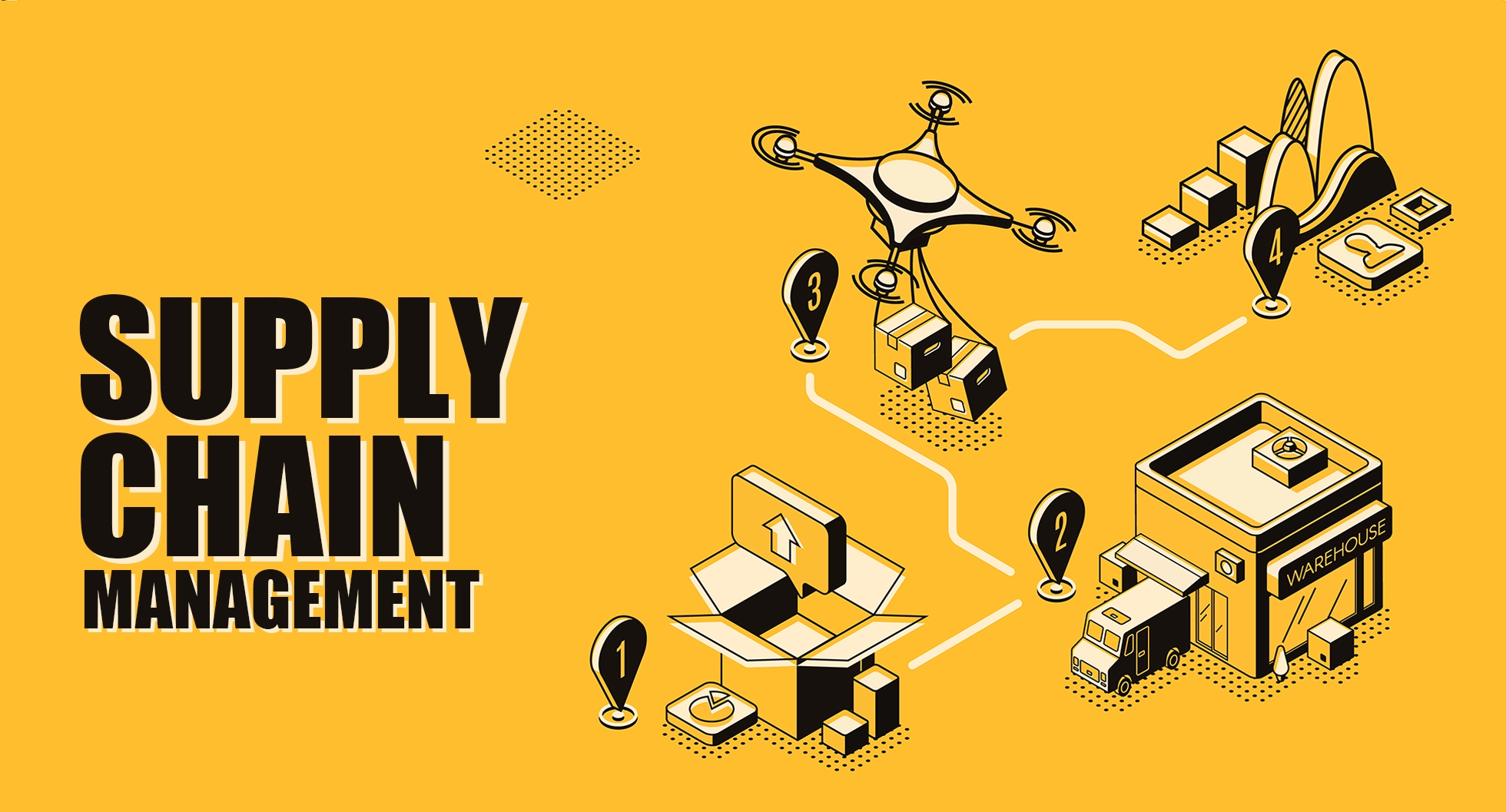

In today’s globalized world, Supply Chain Management (SCM) plays a crucial role in ensuring that goods and services move efficiently from manufacturers to consumers. A well-structured supply chain enables businesses to reduce costs, improve efficiency, enhance customer satisfaction, and gain a competitive advantage.

This article provides an overview of Supply Chain Management (SCM), its key components, core processes, and importance in modern business operations.

1. What is Supply Chain Management (SCM)?

Supply Chain Management (SCM) refers to the strategic coordination of activities involved in sourcing, producing, and delivering goods and services. It covers the entire lifecycle of a product, from raw material procurement to final customer delivery.

1.1 Objectives of SCM

SCM aims to:

✔ Optimize efficiency – Reduce waste, streamline production, and lower costs.

✔ Enhance customer satisfaction – Ensure timely delivery of high-quality products.

✔ Increase profitability – Improve financial performance by managing resources effectively.

✔ Minimize risks – Identify and address disruptions in the supply chain.

✔ Improve sustainability – Implement eco-friendly practices to reduce environmental impact.

A well-managed supply chain enhances a company’s operational success and customer service capabilities.

2. Key Components of Supply Chain Management

A supply chain consists of multiple interconnected components that work together to move products from suppliers to consumers. The key components include:

2.1 Suppliers

- Suppliers provide the raw materials, components, and parts required for production.

- Strong supplier relationships ensure quality, reliability, and cost-effectiveness.

2.2 Manufacturers/Producers

- Convert raw materials into finished products through manufacturing processes.

- Efficient production management ensures cost control, quality assurance, and timely output.

2.3 Warehousing & Inventory Management

- Warehouses store raw materials, work-in-progress, and finished goods.

- Inventory management systems ensure optimal stock levels to meet demand without overstocking or shortages.

2.4 Distribution & Logistics

- Transportation, shipping, and freight services move products through the supply chain.

- Efficient logistics reduce costs and ensure on-time delivery.

2.5 Retailers & Customers

- Retailers sell products to end customers through stores or e-commerce platforms.

- Customer feedback helps businesses improve products and supply chain processes.

Each component must work in synchronization to achieve a smooth and cost-effective supply chain.

3. Core Processes of Supply Chain Management

To function effectively, a supply chain relies on several essential processes that ensure efficiency and responsiveness.

3.1 Procurement (Sourcing & Purchasing)

- Involves selecting and managing suppliers, negotiating contracts, and purchasing raw materials.

- Effective procurement ensures cost efficiency and high-quality inputs.

3.2 Production & Manufacturing

- Transforms raw materials into finished goods through efficient production methods.

- Involves processes such as assembly, packaging, and quality control.

3.3 Inventory Management

- Maintains optimal stock levels to meet demand while minimizing storage costs.

- Utilizes inventory tracking systems, demand forecasting, and automated replenishment.

3.4 Logistics & Transportation

- Ensures efficient movement of goods through various modes of transportation (trucks, ships, rail, air).

- Includes route optimization, carrier selection, and freight cost management.

3.5 Order Fulfillment & Distribution

- Manages order processing, packaging, and shipping to ensure timely deliveries.

- Uses warehouse management systems (WMS) and distribution networks to fulfill customer orders.

3.6 Customer Service & Returns Management

- Addresses customer inquiries, complaints, and product returns.

- A responsive customer service strategy enhances brand reputation and loyalty.

By optimizing these core processes, businesses can achieve a resilient and high-performing supply chain.

4. Importance of Supply Chain Management

Effective SCM provides several benefits that enhance business performance and competitiveness.

4.1 Cost Efficiency

✔ Reduces operational expenses by minimizing waste, inventory costs, and transportation inefficiencies.

4.2 Improved Customer Satisfaction

✔ Ensures on-time deliveries, high-quality products, and reliable service, leading to better customer experiences.

4.3 Risk Mitigation

✔ Helps identify and manage supply chain disruptions, such as supplier failures or geopolitical risks.

4.4 Competitive Advantage

✔ A well-optimized supply chain allows businesses to offer better prices and faster service than competitors.

4.5 Sustainability & Environmental Responsibility

✔ Companies can implement eco-friendly sourcing, energy-efficient transportation, and waste reduction practices.

SCM is not just about moving products—it is about delivering value to customers while maintaining profitability and sustainability.

5. Challenges in Supply Chain Management

Despite its benefits, SCM faces several challenges that businesses must overcome:

❌ Supply Chain Disruptions – Natural disasters, pandemics, and geopolitical issues can disrupt supply chains.

❌ Fluctuating Demand – Unexpected changes in consumer demand can cause inventory imbalances.

❌ Globalization Risks – Cross-border trade complexities, tariffs, and compliance issues affect supply chains.

❌ Technology Integration – Implementing digital solutions like AI, IoT, and blockchain requires investment.

To address these challenges, companies are adopting digital transformation, automation, and data-driven decision-making.

6. Future Trends in Supply Chain Management

As technology and global trade evolve, several trends are shaping the future of SCM:

🔹 Artificial Intelligence (AI) & Automation – AI-driven forecasting and robotic process automation (RPA) enhance efficiency.

🔹 Blockchain for Transparency – Improves supply chain visibility and security by preventing fraud.

🔹 Green & Sustainable Supply Chains – Companies are shifting to carbon-neutral logistics and ethical sourcing.

🔹 E-commerce & Last-Mile Delivery Innovations – Faster, flexible delivery options are reshaping logistics.

Businesses must embrace innovation to build resilient, agile, and future-ready supply chains.

Conclusion

Supply Chain Management (SCM) is the backbone of modern commerce, ensuring the seamless movement of goods and services from suppliers to customers. By optimizing procurement, production, logistics, inventory, and customer service, companies can reduce costs, improve efficiency, and enhance customer satisfaction.

With advancements in technology, sustainability, and automation, the future of SCM promises even greater efficiency and resilience. Organizations that invest in smart supply chain strategies will gain a competitive edge in the global market.